PIB MASTERBATCHES

Our PIB Masterbatch is made in a unique percentage of special type Polyisobutylene that has a high molecular weight and LLDPE and Elastomers. It is the perfect composition of Polyisobutylene & processing additive dispersed in the polymer matrix suitable even for extreme climatic conditions. This PIB MASTERBATCH is available in the form of granules and is easy to mix during the production of Stretch Film, Cling Film, & Wrap Film (either Blown Film or Cast Film) of LLDPE OR LDPE as compared to PIB in liquid form.

APPLICATIONS OF PIB MASTERBATCHES

Stretch Film

Cling Film

Wrap Film

FEATURES OF PIB MASTERBATCH

- Throughout the film, the distribution is consistent.

- Outstanding strength, tackiness, and self-adhesive properties.

- Simple to use.

- Balanced Peel and lap characteristics, good attack, and noise level.

- Oxygen permeability resistance.

- UV stabilisers, antifog, and anticorrosive additives are all compatible.

- Natural Pallet Translucent Physical Appearance.

- Compatibility: LDPE, LLDPE, PP, EVA, and other materials.

- Bulk Loose 0.44 0.55 Gms/cm3 density

Specific Gravity (Gms/cm3): 0.910 0.925.

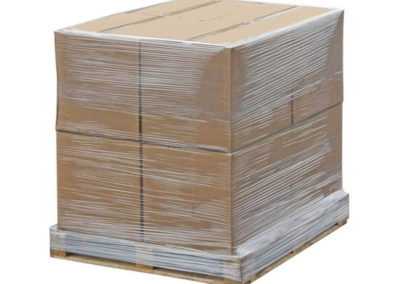

Packaging

STANDARD APPLICATION FOR PALLET STRETCH FILMS REQUIREMENTS & PROFILE

- The thickness of the film ranges from 15 to 25m.

- Extrusion of cast film: main method of conversion.

- Coextruded structures with 3 to 7 layers.

- PIB in masterbatch, liquid PIB, polyolefin elastomer, U-LDPE are the most common cling solutions.

FOOD STRETCH FILMS

STANDARD APPLICATION PROFILE & REQUIREMENTS

- The film thickness ranges from 8 to 15 m.

- Cast Extrusion of the film: The primary method of conversion

- Coextruded structures with 3 to 7 layers

- PIB in masterbatch; Polyolefin Elastomer; PVC is the primary cling solutions.